Nitrogen generator (MNG model)

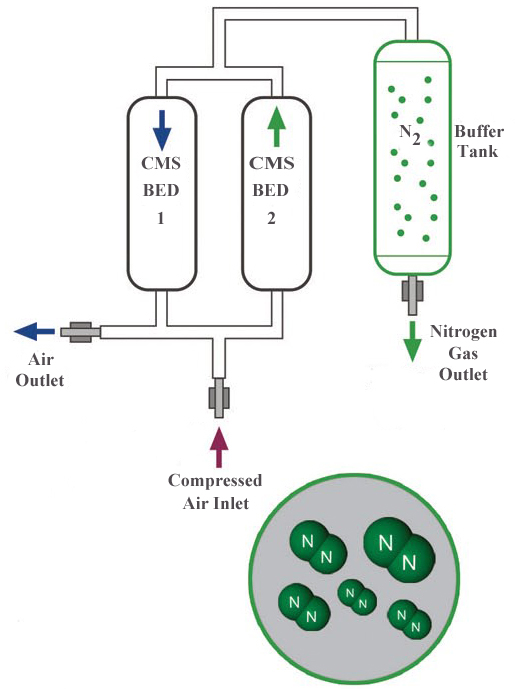

Pressure Swing Absorption (PSA): A nitrogen generator is a system for separating and enriching nitrogen from oxygen.

Processing (Carbon Molecular Sieve): For molecular sieve carbon adsorbs oxygen and water vapor molecules under a certain pressure, while allowing nitrogen to pass through.

How the nitrogen generator works:

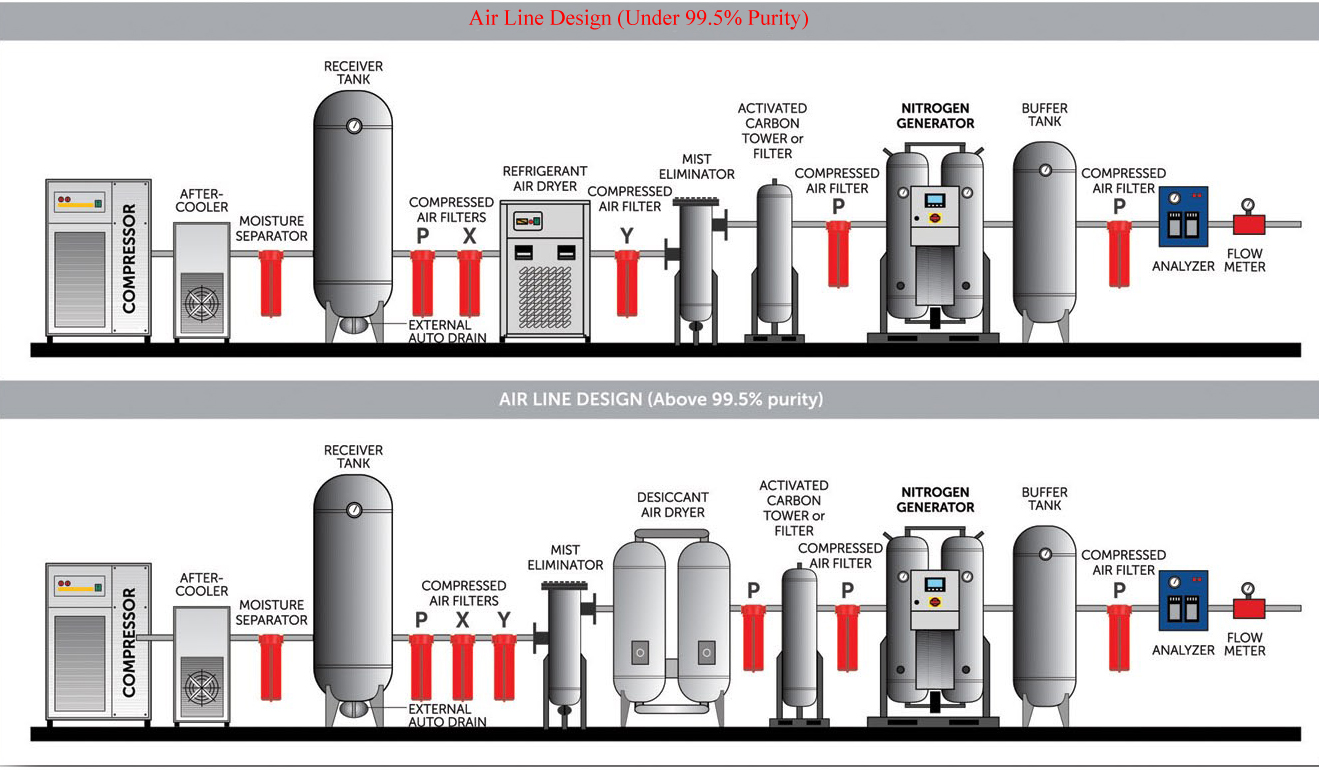

The nitrogen generator works on the principle of pressure absorption to produce a continuous stream of nitrogen gas from compressed air. This system consists of 2 absorption towers filled with absorbent material called molecular carbon, which compressed air enters the towers after passing through the water and oil particle filters. Oxygen and other gases are absorbed by the processing system and allow nitrogen to pass through. When one tower performs an absorption action, material regeneration is automatically performed in the other tower by reducing the pressure.

Molecular sieve carbon is different from ordinary activated carbon and has a wide range of holes. In this case, it allows small molecules such as oxygen to penetrate it and separate from nitrogen molecules, because nitrogen molecules are too big to enter the processing section.

Larger nitrogen molecules pass through the processing section and appear as gas production, the purity of nitrogen gas can be provided in different capacities. (This value is 99.999 percent.)

Application of nitrogen generator:

The nitrogen generator manufactured by Behsan can be used in the following industries:

- Metal Industry

- chemical industry

- Food production and storage process

- Plastic industry

- Covering nitrogen gas in resistant chambers

- Safe against gas ignition

The unique features of the nitrogen generator (MNG model):

- Simple structure, compact design

- Fully automatic operation

- 24/7 production of nitrogen inside the device (photo 1)

- PLC touch screen for accurate and complete control of the system (photo 2)

- PLC screen to search the whole system

- Fast and safe launch system

- Due to the good design of the muffler, the noise level is low when pressing and wiping. (photo 4)

- Durable piston valves for long life (photo 5)

- Designing the purity and capacity of nitrogen gas according to customer needs (Nitrogen purity 95~99.999% is available.)

- Minimum amount of maintenance cost; Only need to change the filter and normal service for the compressor